Bullseye Agilent 536 KF25 Vacuum Sensor

The Agilent 536 KF25 Vacuum Sensor is a type of vacuum pressure sensor designed for use in vacuum systems, providing precise measurement of vacuum levels.

This specific sensor uses the KF25 (Klein Flange 25) fitting, which is a standard flange size used for vacuum connections, particularly in laboratories and industrial vacuum systems.

Key Features and Characteristics:

-

Vacuum Pressure Measurement:

- The Agilent 536 is designed to accurately measure the pressure in high and ultra-high vacuum systems. It can be used to monitor and control vacuum conditions in various applications, ensuring they are within the desired range.

-

Vacuum Fitting (KF25):

- The KF25 fitting refers to the size of the flange on the sensor, specifically 25 mm, which is common in scientific and industrial vacuum applications. The "KF" designates a quick-flange coupling that allows for easy and reliable connections between the sensor and other vacuum components.

-

Measurement Range:

- The Agilent 536 typically offers a wide measurement range, which makes it suitable for both medium and high-vacuum systems. The pressure range it covers typically spans from atmospheric pressure down to ultra-high vacuum levels, measured in torr, millibar, or Pascal units.

-

Sensor Technology:

- It uses capacitive or piezoelectric technology to sense pressure. These types of sensors are known for their accuracy and reliability, providing real-time pressure data.

- Capacitive sensors work by measuring changes in capacitance as the pressure varies, offering high sensitivity at low pressure levels.

-

Output and Display:

- The Agilent 536 sensor is often connected to a vacuum controller or gauge readout, where it provides data about the system's pressure. It might offer digital output signals (e.g., analog voltage, 4-20 mA, or digital communication) to integrate with larger vacuum systems or laboratory equipment.

-

Applications:

- Research and Development: Often used in research environments that require precise vacuum control, such as material science, semiconductor fabrication, and pharmaceutical production.

- Industrial Vacuum Systems: Used in industries like electronic manufacturing, food packaging, vacuum coating, and environmental testing, where maintaining specific vacuum levels is critical.

-

Accuracy and Calibration:

- Agilent sensors are designed for high accuracy and reliable performance over time. The sensor is typically factory calibrated and can maintain its accuracy within a specified range. Calibration ensures that the readings remain consistent, which is vital for precision operations.

-

Compatibility:

- The KF25 flange allows for easy integration with other vacuum components that use the same flange standard, making the Agilent 536 sensor highly versatile in various systems.

Conclusion:

The Agilent 536 KF25 Vacuum Sensor is an accurate, reliable tool designed for use in vacuum applications. It provides precise pressure readings over a broad range and is suitable for both scientific research and industrial vacuum systems.

The KF25 flange ensures compatibility with a wide variety of vacuum equipment, making it a versatile and essential component in managing vacuum systems.

Bullseye Agilent 536 KF25 Vacuum Sensor

The Agilent 536 KF25 Vacuum Sensor is a type of vacuum pressure sensor designed for use in vacuum systems, providing precise measurement of vacuum levels.

This specific sensor uses the KF25 (Klein Flange 25) fitting, which is a standard flange size used for vacuum connections, particularly in laboratories and industrial vacuum systems.

Key Features and Characteristics:

-

Vacuum Pressure Measurement:

- The Agilent 536 is designed to accurately measure the pressure in high and ultra-high vacuum systems. It can be used to monitor and control vacuum conditions in various applications, ensuring they are within the desired range.

-

Vacuum Fitting (KF25):

- The KF25 fitting refers to the size of the flange on the sensor, specifically 25 mm, which is common in scientific and industrial vacuum applications. The "KF" designates a quick-flange coupling that allows for easy and reliable connections between the sensor and other vacuum components.

-

Measurement Range:

- The Agilent 536 typically offers a wide measurement range, which makes it suitable for both medium and high-vacuum systems. The pressure range it covers typically spans from atmospheric pressure down to ultra-high vacuum levels, measured in torr, millibar, or Pascal units.

-

Sensor Technology:

- It uses capacitive or piezoelectric technology to sense pressure. These types of sensors are known for their accuracy and reliability, providing real-time pressure data.

- Capacitive sensors work by measuring changes in capacitance as the pressure varies, offering high sensitivity at low pressure levels.

-

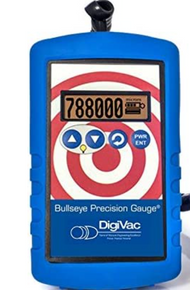

Output and Display:

- The Agilent 536 sensor is often connected to a vacuum controller or gauge readout, where it provides data about the system's pressure. It might offer digital output signals (e.g., analog voltage, 4-20 mA, or digital communication) to integrate with larger vacuum systems or laboratory equipment.

-

Applications:

- Research and Development: Often used in research environments that require precise vacuum control, such as material science, semiconductor fabrication, and pharmaceutical production.

- Industrial Vacuum Systems: Used in industries like electronic manufacturing, food packaging, vacuum coating, and environmental testing, where maintaining specific vacuum levels is critical.

-

Accuracy and Calibration:

- Agilent sensors are designed for high accuracy and reliable performance over time. The sensor is typically factory calibrated and can maintain its accuracy within a specified range. Calibration ensures that the readings remain consistent, which is vital for precision operations.

-

Compatibility:

- The KF25 flange allows for easy integration with other vacuum components that use the same flange standard, making the Agilent 536 sensor highly versatile in various systems.

Conclusion:

The Agilent 536 KF25 Vacuum Sensor is an accurate, reliable tool designed for use in vacuum applications. It provides precise pressure readings over a broad range and is suitable for both scientific research and industrial vacuum systems.

The KF25 flange ensures compatibility with a wide variety of vacuum equipment, making it a versatile and essential component in managing vacuum systems.