Here’s a detailed description:

-

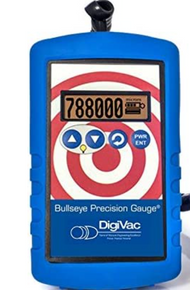

Design and Display:

- The gauge typically features a clear, easy to read digital display.

-

Accuracy:

- These gauges are known for their high precision in measuring very low pressure (vacuum) levels. They are capable of detecting minute fluctuations in vacuum pressure, ensuring accurate readings for sensitive applications.

-

Measurement Range:

- Bullseye vacuum gauges generally measure pressures in the high vacuum or ultra-high vacuum range. This can range from atmospheric pressure down to extremely low pressures in the torr, pascal, or millibar range.

-

Working Principle:

- These gauges use various technologies like Capacitive, Piezoelectric, or Ionization sensors to detect pressure. The choice of technology depends on the specific application, with some models being more suitable for ultra-high vacuum conditions and others for standard high-vacuum environments.

-

Applications:

- Scientific Research: They are crucial in fields like physics, materials science, and nanotechnology where maintaining specific vacuum conditions is essential for experiments.

- Industrial and Manufacturing: Vacuum systems in industries like semiconductor manufacturing, food packaging, and electronics also rely on precision gauges to ensure optimal performance.

- Laboratory Use: They are employed in laboratory settings for processes like material deposition, testing, or in devices like electron microscopes.

-

Calibration:

- Many Bullseye vacuum gauges are calibrated for high accuracy, ensuring that readings remain consistent over time. Calibration may require external calibration equipment or can be done through software if the model supports digital interfacing.

In short, the Bullseye Precision Vacuum Gauge is a reliable and accurate tool designed to measure vacuum pressure, offering excellent precision and clarity for a wide range of professional and industrial applications.

Agilent 536 KF25 Vacuum Sensor

is a vacuum pressure sensor designed for use in vacuum systems, providing precise measurement of vacuum levels.

This specific sensor uses the KF25 (Klein Flange 25) fitting, which is a standard flange size used for vacuum connections, particularly in laboratories and industrial vacuum systems.

Here’s a detailed breakdown of the Agilent 536 KF25 Vacuum Sensor:

Key Features and Characteristics:

-

Vacuum Pressure Measurement:

- The Agilent 536 is designed to accurately measure the pressure in high and ultra-high vacuum systems. It can be used to monitor and control vacuum conditions in various applications, ensuring they are within the desired range.

-

Vacuum Fitting (KF25):

- The KF25 fitting refers to the size of the flange on the sensor, specifically 25 mm, which is common in scientific and industrial vacuum applications. The "KF" designates a quick-flange coupling that allows for easy and reliable connections between the sensor and other vacuum components.

-

Measurement Range:

- The Agilent 536 typically offers a wide measurement range, which makes it suitable for both medium and high-vacuum systems. The pressure range it covers typically spans from atmospheric pressure down to ultra-high vacuum levels, measured in torr, millibar, or Pascal units.

-

Sensor Technology:

- It uses capacitive or piezoelectric technology to sense pressure. These types of sensors are known for their accuracy and reliability, providing real-time pressure data.

- Capacitive sensors work by measuring changes in capacitance as the pressure varies, offering high sensitivity at low pressure levels.

-

Output and Display:

- The Agilent 536 sensor is often connected to a vacuum controller or gauge readout, where it provides data about the system's pressure. It might offer digital output signals (e.g., analog voltage, 4-20 mA, or digital communication) to integrate with larger vacuum systems or laboratory equipment.

-

Applications:

- Research and Development: Often used in research environments that require precise vacuum control, such as material science, semiconductor fabrication, and pharmaceutical production.

- Industrial Vacuum Systems: Used in industries like electronic manufacturing, food packaging, vacuum coating, and environmental testing, where maintaining specific vacuum levels is critical.

-

Accuracy and Calibration:

- Agilent sensors are designed for high accuracy and reliable performance over time. The sensor is typically factory calibrated and can maintain its accuracy within a specified range. Calibration ensures that the readings remain consistent, which is vital for precision operations.

-

Compatibility:

- The KF25 flange allows for easy integration with other vacuum components that use the same flange standard, making the Agilent 536 sensor highly versatile in various systems.

Conclusion:

The Agilent 536 KF25 Vacuum Sensor is an accurate, reliable tool designed for use in vacuum applications. It provides precise pressure readings over a broad range and is suitable for both scientific research and industrial vacuum systems. The KF25 flange ensures compatibility with a wide variety of vacuum equipment, making it a versatile and essential component in managing vacuum systems.