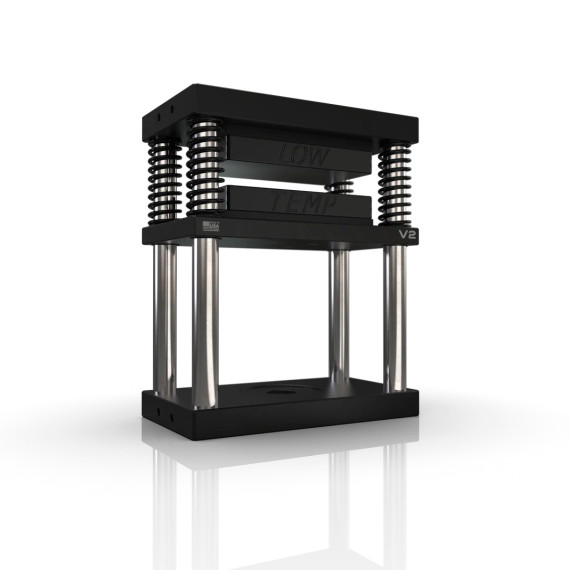

The Lowtemp Tall V2 Rosin Press Bundle offers a professional-grade pressing platform with a modular frame and advanced LT3 touchscreen controller. It’s the ideal mid-tier solution for those seeking more power and control than a basic DIY setup—without committing to a full BVA hydraulic press system. Simply add your own 10–20 ton bottle jack to activate this ready-to-press bundle.

The LT3 is a state-of-the-art heat controller engineered for precision and modern functionality. It supports Bluetooth for wireless data logging, over-the-air firmware upgrades, recipe storage, and automated platen pressure tracking—accessible via a vivid, user-friendly touchscreen.

The crisp, high-resolution display provides straightforward access to temperature, pressure, and system settings, allowing users to monitor and fine-tune performance effortlessly.

Both platens can be controlled independently, allowing precise heat management and uniform temperature across surfaces.

The system’s advanced pressure mapping function offers instant feedback on pressure balance, helping users achieve accurate and efficient operation.

Built-in stopwatch and countdown timer functionality, combined with the ability to save and retrieve settings, support consistent and repeatable processes.

With the integration of a 0–10,000 psi sensor, the LT3 offers real-time calculation and display of platen pressure for optimal process control.

Smart detection technology identifies the exact point when set parameters are reached, helping avoid over-processing and maximizing consistency.

Operational data is securely stored and can be retrieved for performance evaluation, troubleshooting, or optimization.

Stay current with automatic delivery of new features and performance enhancements via over-the-air updates—no manual downloads required.

Fully backwards-compatible with all existing Lowtemp Presses, Plate Kits, and Cage Kits. Its modular configuration ensures simple integration and component replacement.

Manufactured in the United States using premium-grade materials to deliver unmatched quality and durability.

Engineered for Bottle Jack Use

The Lowtemp V2 unit is specifically built to operate with a standard bottle jack. For best performance, a jack rated up to 20 tons is recommended.

Lowtemp plate and cage assembly

(Optional) LT3 heat controller

(Optional) Integrated pressure sensor

Modular design for flexible upgrades

Available in six color finishes

Food-grade anodized and insulated plates

Rugged powder-coated steel frame

Constructed in Denver, Colorado using certified American alloys

Compatible with LT3 controller and pressure sensor (optional)

Lifetime warranty on the mechanical press

1-year full warranty on all electronic components

Supports force application up to 20 tons

This bundle does not include a hydraulic press or bottle jack. A 10–20 ton hydraulic jack (manual or air-powered) is required for full operation. For a complete plug-and-play solution, see our fully integrated Lowtemp V2 press systems.

The Lowtemp Tall V2 Rosin Press Bundle offers a professional-grade pressing platform with a modular frame and advanced LT3 touchscreen controller. It’s the ideal mid-tier solution for those seeking more power and control than a basic DIY setup—without committing to a full BVA hydraulic press system. Simply add your own 10–20 ton bottle jack to activate this ready-to-press bundle.

The LT3 is a state-of-the-art heat controller engineered for precision and modern functionality. It supports Bluetooth for wireless data logging, over-the-air firmware upgrades, recipe storage, and automated platen pressure tracking—accessible via a vivid, user-friendly touchscreen.

The crisp, high-resolution display provides straightforward access to temperature, pressure, and system settings, allowing users to monitor and fine-tune performance effortlessly.

Both platens can be controlled independently, allowing precise heat management and uniform temperature across surfaces.

The system’s advanced pressure mapping function offers instant feedback on pressure balance, helping users achieve accurate and efficient operation.

Built-in stopwatch and countdown timer functionality, combined with the ability to save and retrieve settings, support consistent and repeatable processes.

With the integration of a 0–10,000 psi sensor, the LT3 offers real-time calculation and display of platen pressure for optimal process control.

Smart detection technology identifies the exact point when set parameters are reached, helping avoid over-processing and maximizing consistency.

Operational data is securely stored and can be retrieved for performance evaluation, troubleshooting, or optimization.

Stay current with automatic delivery of new features and performance enhancements via over-the-air updates—no manual downloads required.

Fully backwards-compatible with all existing Lowtemp Presses, Plate Kits, and Cage Kits. Its modular configuration ensures simple integration and component replacement.

Manufactured in the United States using premium-grade materials to deliver unmatched quality and durability.

Engineered for Bottle Jack Use

The Lowtemp V2 unit is specifically built to operate with a standard bottle jack. For best performance, a jack rated up to 20 tons is recommended.

Lowtemp plate and cage assembly

(Optional) LT3 heat controller

(Optional) Integrated pressure sensor

Modular design for flexible upgrades

Available in six color finishes

Food-grade anodized and insulated plates

Rugged powder-coated steel frame

Constructed in Denver, Colorado using certified American alloys

Compatible with LT3 controller and pressure sensor (optional)

Lifetime warranty on the mechanical press

1-year full warranty on all electronic components

Supports force application up to 20 tons

This bundle does not include a hydraulic press or bottle jack. A 10–20 ton hydraulic jack (manual or air-powered) is required for full operation. For a complete plug-and-play solution, see our fully integrated Lowtemp V2 press systems.